Used Ruhle Curing Machine PR 20 Injectors

U/M: Each

Stock: Out Of Stock

Shipping Dimension: 50 X 20 X 56

Shipping Weight: 287 lbs

CM: 555

Used Ruhle Curing Machine PR 20 Injectors

The reliable multi-talent

The curing machines from 8 to 20 needles in their timeless metal frame offer modern curing technology with accurate injection, good work performance and best cleaning properties. Equipped with a softer, a handinjector and a powerful stainless steel pump, all curing products, with or without bones, await the right equipment for perfect results.

Technical Details

| Height of machine: | 1600 mm |

| Length of machine: | 1320 mm |

| Width of machine: | 550 mm |

| Connected load: | 1,5 kW |

| Weight of machine: | 130 kg |

| Performance: | 2000 kg/h |

| Belt advance feed: | 28 mm/step |

| Belt width: | 300 mm |

| Rows of needles: | 2 |

| Feed inlet height: | 180 mm |

The softer

The softer works simular to a steaker with unique angled knives, which create surgical cuts inside the meat structure and tendons after the injection. This is how the tissue structure of the meat is loosened up and it activates the meat’s own softer actomysin. This makes the meat more tender and improves the protein breakdown and the liquid retention.

The pressure system

The large volume stainless steel pumps guarantee permanent use where wear and tear doesn’t matter at all. Stable pressures from 0,5 to 4,3 bar allow for a reliable transport of even viscuous liquids with repeat accuracy. Natural aspiration of 10 metres and the insensitivity towards salt cristals and pieces of ice make the process safe and the circulation shorter.

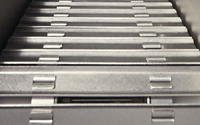

The conveyor belt

The stainless steel conveyor belt is not only stabil but gives the product a good grip so that a forward feed accurate to the millimeter can be achieved. Differing injection gaps are nearly impossible. Salt, protein and other agressive materials don’t have a chance when it comes to stainless steel. There is no unhygienic discolouration or pitting.

The needle system

The basic equipment of each machine contains springs which are able to help penetrating thick skin but are soft enough to avoid splintering of the bone. The flexible needle bearing system allows the needles to move around very hard objects in order to avoid brakeage or excessive wear and tear as could normaly happen when curing pig’s head.

The hand injector

Owners of small to medium sized curing machines have to cure a piglet now and then. A hand injector is available for this very reason. This makes it possible to solve oversized curing tasks with the help of the complete curing technology. You have enough pressure in your hand injector and there is no need to buy a second machine.

The cleaning position

It only takes three steps and the whole working area is opened up and accessible from all sides. The conveyor belt disengages automatically so that it only takes one move to bring it into a comfortable cleaning position. The complete cleaning process doesn’t take more than 5 minutes and assembling as well as dismounting is done in 20 seconds.

Equipment

- Stainless steel XXL impeller pump

- Stainless steel belt with grip ridges

- Welded machine construction

- Standard carriage clearance underneath

- Automatic belt fastening

- Processing area, which unfolds

- CE und GS test certificate

Accessories

- Poultry accessories

- Fish accessories

- Softer

- Individual needle injection gun

Brochure

Brochure

-142x142.JPG)

-142x142.JPG)

-142x142.JPG)

-142x142.JPG)

-238x94.jpg)