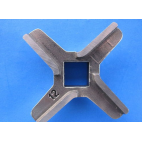

Nock Circular Blade Cutting Cortex CB 435/4E HVC

Type: cutting width: 300mm

Country of Origin: Germany

Ships from: FOB Brampton, ON Canada (O)

U/M: Each

Stock: On Order

CM: 8119

Country of Origin: Germany

Ships from: FOB Brampton, ON Canada (O)

U/M: Each

Stock: On Order

CM: 8119

Financing Available

Note: Shipping to be determined

Nock Cortex CB 435/4E HVC Horizontal Vertical Circular blade cutting machine

Cutting machine with a band blade for 1 horizontal cut and circular blade cutting unit for vertical cuts.

Features:

- For 1 horizontal cut plus many vertical cuts, only 1 horizontal cut, or only vertical cuts

- Thickness of the horizontal cut is infinitely adjustable from approx. 1mm

- Distance of circular blades is adjustable in steps

Application:

- Perfect for cutting e.g. strips of chicken breast or turkey meat, thin scallops, fish fillets for sushi, etc.

- No water or compressed air requirement

Standard:

- Band blade for 1 horizontal cut

- Horizontal cutting model with upper pressure conveyor

- Circular blade cutting unit for various vertical cuts

- Infeed conveyor

- Discharge conveyor

- Intersection roller for circular blades with quick change system

- NOCK POWER PLATES for typical NOCK service friendliness

- NOCK EASY-FLOW with pneumatic springs for exemplary operational safety

- Lift out device for blade shaft

- Lockable castors

- Stainless steel

Technical Specifications:

- Blade Diameter: 200mm

- Max. throughput height: 70mm

- Operational width: band blade 380mm / circular blade-stocking max. 300mm

- Conveyor belt width: 370mm

- Max. throughput width: 410mm

- Conveyor belt speed: 25m/min

- Min. blade distance (technical limit): 600 (depending on product)

- Available circular blade distance grids: 6-7-8-9-10-11mm

- Overall dimension: 1520x1530x2420mm (WxHxD)

- Weight: 385 kg (with 8mm blade distance)

- Motor performance: 1.3kW (0.75kW + 0.55kW)

- Voltage: 400V 50Hz 3Ph (other voltage options available)

Options:

- Pressure roller for horizontal cutting model

- Separation conveyor for separate discharge of the upper slice

- Cleaning wagon for 2 blade shafts

- Other operational speeds

- Frequency converter

- Scraper on discharge conveyor

- 90° cutting system to slice cubes

Brochure

Brochure

-238x94.jpg)