HTS 150S Vacuum Filler

The HTS 150S is a versatile machine designed for individual applications. It is ideally suited for companies who offer a wide range of products and must work efficiently. This is achieved by a specially designed conveying system that guarantees a constant filling process with minimized residual quantities. This is further complemented by a dynamic and powerful servo drive. The hardened materials used for the conveying mechanism meets high requirements and guarantees long durability. Various accessory devices and clip machines can be controlled via an optional signal connector.

Basic equipment and technical data:

The HTS Touchscreen is very comfortable and easy to operate with its clear symbolic language.

With adjustment of the acceleration ramp for main-drive and twist system, weight correction.

Statistics will inform about daily, monthly, yearly and total machine output. Safety shutdowns

and error messages from the digital drive system are displayed and diagnosed.

Possibility to store a special software specified for customer.

The Dynamic all-rounder

The 150 S model is equipped with the HTS 250 industrial conveyor system and therefore offers the possibility of processing larger pieces of meat.

The HTS 250 industrial conveyor system enables raw sausage products to be processed even more gently.

The HTS 150 S is designed for individual use, especially when a wide variety of crops is involved.

Rationality is required. This is achieved through a special interpretation of the

Conveyor system. This results in a consistent filling process with minimal residual quantities.

This is rounded off by the high dynamics of the powerful servo drive.

Hardened materials of the conveyor allow high demands with long running times.

Additional equipment or clipping machines can be connected via the standard signal socket

be controlled.

HTS 150 S is characterized by:

Efficient work

Minimal residual quantities

Easy variety change

High portioning accuracy

Compact design

Standard equipment:

+ 250-liter folding funnel

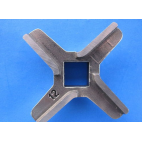

+ Slide drum pitch 16

+ Keyboard control

+ Signal socket for additional devices

or clipping machines

+ 3 filling nozzles of choice, tools, grease press, mirror, documentation

Performance data:

Filling capacity: 4,300 kg/h

Filling pressure: 35 bar

Hopper capacity: 250 liters

Portioning range: 1 to 100,000 g

Portions of 30 grams: 550 (maximum per minute)

Portions of 70 grams: 480 (maximum per minute)

Portions of 100 grams: 420 (maximum per minute)

Connected load: 7.5kW

Options:

-modern touch screen control

-Mast lifting device

-350L hopper

-Vacuum pump 40m

-238x94.jpg)