Stage 4: Industrial Bone Paste Emulsifier (CM-240)

U/M: Each

Stock: On Order

HTS Code:8438.50.00.90 CM: 8703

Stage 4: Industrial Bone Paste Emulsifier (CM-240)

The Stage 4 Paste Maker is the final refinement step in the industrial bone processing line. It is a specialized colloid mill designed to take the ground output from Stage 3 and pulverize it into a superfine, micron-level paste (80-200 mesh).

Step 4: Final Product Refinement

Input Requirement: This machine is designed to be fed with Fine Ground Mince.

For continuous production, this unit connects directly to the output of our Stage 3 Grinder (CM-250). The pre-ground meat/bone mix is essential for the mill to operate efficiently at high speed.

« View Previous Step: Stage 3 Grinder

INPUT A: Bulk Feed Volume

INPUT B: Fine Mince Texture

Machine Operation Videos

Video 1: Standard Operation Demo

Video 2: Performance & Consistency View

Features of the Bone Paste Grinding Machine

The resulting shear force effectively breaks down the bone and meat materials into a fine paste. The bone paste grinding machine is equipped with a cooling system to prevent overheating during the grinding process, ensuring the quality and safety of the final product.

- 1. Versatile application: This machine is capable of grinding various types of animal bones and meat, making it suitable for a wide range of industries.

- 2. High efficiency: The powerful motor and unique design of the grinding mechanism ensure a high production capacity and consistent results.

- 3. Hygienic and easy to clean: The machine is made of high-quality stainless steel, ensuring food safety and easy cleaning for optimal hygiene standards.

- 4. Adjustable grinding fineness: The grinding fineness can be easily adjusted according to specific requirements, allowing for precise control of the final product quality.

- 5. User-friendly operation: The machine is equipped with an intuitive control panel and ergonomic design, making it easy to operate and control the grinding process.

- 6. Energy-efficient and cost-effective: Designed to be energy-efficient, reducing operational costs while maintaining high productivity.

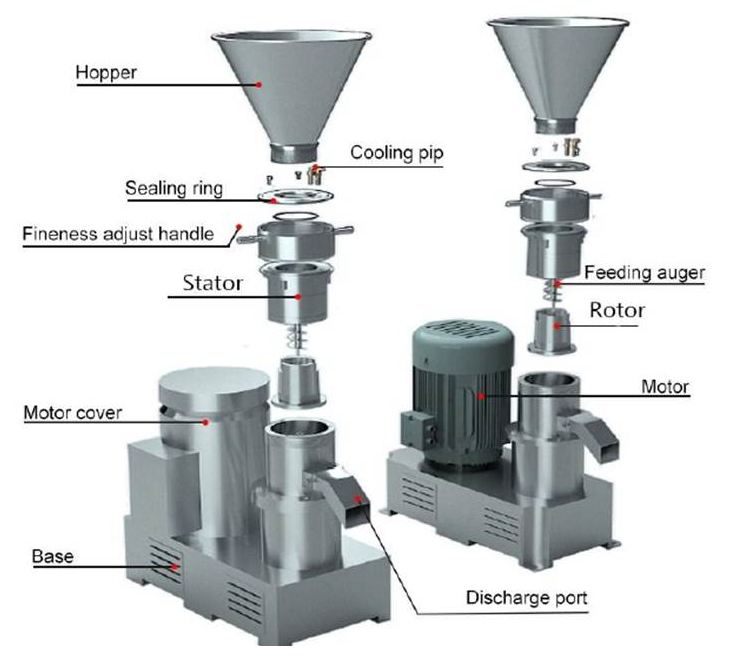

Technical Layout & Setup

Figure 1: Machine Parts & Assembly Setup

Technical Specifications (All Models)

| Specs | Model CM-80 | Model CM-180 | Model CM-210 | Model CM-240 (Recommended) | Model CM-300 |

|---|---|---|---|---|---|

| Fineness/Mesh | 80/150 | 80/200 | 80/200 | 80/200 | 80/200 |

| Capacity (kg/hr) | 60 - 80 | 700 - 800 | 1000 - 1200 | 1200 - 1500 | 3000 - 4000 |

| Power (kW) | 4 kW | 18.5 kW | 30 kW | 45 kW | 75 kW |

| Hopper Volume | 8 Litres | 14 Litres | 24 Litres | 24 Litres | 32 Litres |

| Dimensions (mm) | 640x410x900 | 830x490x1100 | 1260x600x1230 | 1330x630x1280 | 1440x680x1420 |

| Weight (kg) | 150 | 375 | 700 | 920 | 1300 |

-80x80.png)

-80x80.png)

Brochure

Brochure

-238x94.jpg)