Stage 2 Industrial Bone Crusher

Country of Origin: Canada

Ships from: FOB Brampton, ON Canada (O)

U/M: Each

Stock: On Order

Product Dimension: 74 x 41 x 73

Shipping Dimension: 78 X 44 X 63

Shipping Weight: 2,870 lbs

HTS Code:8438.50.00.90 CM: 8425

Stage 2 Crusher: High-Capacity Industrial Bone Processing

The Stage 2 Crusher is a versatile, heavy-duty processing solution engineered to meet the rigorous demands of the pet food industry, agricultural operations, and laboratories.

Designed for high-volume environments, its primary function is the effortless pulverization of pre-broken animal bones into precise particle sizes ranging from 3mm to 15mm.

Step 1: Vital System Integration (Input)

Important: This unit is specifically engineered to refine material that has already been reduced in size.

For optimal efficiency, this unit is best paired with our Stage 1 Pre-Breaker. The output from Stage 1 (shown in the photo) is the ideal feed size to maximize the speed and longevity of the Stage 2 Crusher.

View Stage 1 Pre-Breaker Machine »

INPUT MATERIAL: Pre-crushed bones from Stage 1

? Operational Insight: Why is 2-4 Inches the Ideal Input Size?

Based on the "Stage 1 Output" images and the machine's design as a secondary processor, the recommended input bone size is approximately 2 to 4 inches (50mm – 100mm). Here is why this size is critical for performance:

- 1. The "Pre-Breaker" Standard:

This "fist-sized" chunk is exactly what your Stage 1 Pre-Crusher produces. It is small enough to easily fall into the crushing mechanism but large enough for the rollers to grab effectively. - 2. Machine Longevity:

The Stage 2 Crusher is a "finisher." It is designed to refine material, not break whole carcasses. Feeding it pre-broken chunks (2-4 inches) ensures the 440C blades face consistent wear rather than the shock impact of large, whole bones. - 3. Throughput Speed:

This specific size allows for a continuous flow. If bones are too large (e.g., whole leg bones), they may bounce on top of the rollers before catching, which slows down your 4500 kg/hr production rate.

Step 2: Final Product Results (Output)

The Stage 2 Crusher transforms the rough input into a consistent, high-quality mince ideal for pet food and fertilizer production.

Consistent Mince Texture

High-Volume Output

Premium Construction & Hardened Components

Built for endurance and sanitation, the Stage 2 Crusher is constructed entirely from high-grade stainless steel to strictly adhere to food-grade standards. The internal crushing mechanism is engineered for maximum longevity, featuring:

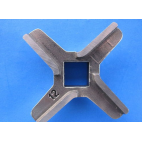

- 440C Material Roller Blades: Hardened for superior wear resistance and extended edge retention.

- Stainless Steel Roller Shafts: Ensuring high strength and corrosion resistance at the machine's core.

The unit also features easy-to-clean technology that provides convenient access to these internal workings, ensuring a bacteria-free sanitization process and minimizing downtime.

Operational Versatility

While capable of crushing various bone types, the Stage 2 Crusher is optimized for processing fresh bones.

It is designed for seamless integration into existing production lines, equipped to discharge directly into a 200L Euro-type buggy or connect to a conveyor system for continuous workflow.

Technical Specifications

| Capacity | 4500 kg/hr± (Dependent on product type) |

| Output Size | Adjustable 3mm – 15mm± |

| Blade Material | 440C Stainless Steel |

| Shaft Material | Stainless Steel |

| Body Construction | Full Stainless Steel body and control box |

| Discharge Options | Accommodates 200L Euro-type buggy or Vertical Conveyor |

Power, Controls & Safety

- Buggy Safety Interlock: Integrated sensor system automatically prevents operation if the collection buggy is removed or not properly positioned.

- Motor: Heavy-duty 11 kW / 14 HP Crusher Motor

- Voltage: Standard 220V / 60Hz / 3Ph

- Controls: Features Power On/Off, Emergency Stop, and Jog Reverse function for clearing jams.

Certification: Conforms to CE Standards

-238x94.jpg)