Ruhle SR2 Turbo Dicer

Country of Origin: Germany

Ships from: FOB Brampton, ON Canada (O)

U/M: Each

Stock: On Order

Shipping Dimension: 69 X 42 X 77

Shipping Weight: 2,095 lbs

CM: 75

Ruhle High Tech Cutting machine SR2 Turbo

This semi-automatic machine has a high cutting rate and produces up to 3,000 kg of cubes, strips, or portions per hour. This performance is due to the large shaft and fast operating speed as well as (and especially) to time-saving features that prevent idle cuts.

Technical Details:

|

|

SR1 Dicer |

SR1 Turbo Dicer |

SR 2 Turbo Dicer |

AR 10 Dicer |

|

Length of Machine |

900 mm |

1000 - 2100 mm |

1550 mm |

1070 – 1900 mm |

|

Width of Machine |

600 mm |

710 - 1400 mm |

900 – 1400 mm |

690 – 890 mm |

|

Height of Machine |

980 mm |

1110 mm |

1300 mm |

1040 mm |

|

Weight of Machine |

280 kg |

325 kg |

850 kg |

245 kg |

|

Connected load |

1,5 kW / 16 A |

2.1 kW / 16 A |

3,5 kW / 16 A |

3.8 kW / 16 A |

|

Width of shaft |

100 mm |

100 mm |

120 mm |

100 mm |

|

Height of shaft |

100 mm |

100 mm |

120 mm |

100 mm |

|

Length of shaft |

350 mm |

350 mm |

500 mm |

350 mm |

|

Section length |

1 - 32 mm |

1 - 32 mm |

0,5 – 32 mm |

0.5 – 60 mm |

|

Sections |

80 per min |

160 per min |

160/320 per min |

200 per min |

|

Cutting temperature |

-5°C - +80°C |

-5°C - +80°C |

-5°C - +80°C |

-5°C - +80°C |

|

Cutting output |

900 kg max. |

1500 kg max. |

3000 kg max. |

1800 kg max. |

|

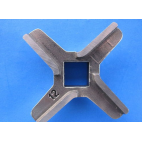

Standard grid-sizes |

1) 5, 10, 20, 50mm 2) 6, 12, 24, 50mm 3) 7, 15, 30, 50mm |

1) 5, 10, 20, 50 2) 6, 12, 24, 50 3)7, 15, 30, 50 |

1) 5, 10, 20, 40, 60 2) 6, 12, 24, 60 3) 7, 15, 30, 60 |

3, 5, 6, 8, 10, 12, 15, 16, 20, 24, 30, 50 |

Brochure

Brochure

-238x94.jpg)