Stage 3 Grinder: Industrial Fresh & Frozen Mincer (CM-250)

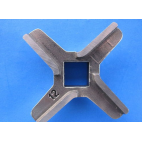

The Stage 3 Grinder (Model CM-250) is the "workhorse" of the industrial bone processing line. Constructed from high-quality stainless steel with a low-noise, reliable structure, it uses a powerful rotary screw mechanism to push material to the precut-plate with immense force.

Designed to accept the 15mm output from Stage 2, it refines the product into a consistent, commercially viable ground meat/bone mince using precise relative movement between the knife and hole-plate.

Step 3: Integrated Workflow

Input Requirement:

For Pet Food & Bone Lines: When intended for dog food production, this machine is optimized to process pre-crushed material (approx. 10mm - 20mm). For the smoothest operation and highest throughput in these applications, this unit should be fed directly by our Stage 2 Roller Crusher. The consistent small chunks ensure the grinder runs at maximum efficiency without jamming.

For Standard Meat Processing: For other standard heavy-duty applications (such as fresh or semi-frozen meat blocks), this powerful unit functions excellently as a standalone grinder and does not require pre-crushed input.

« View Previous Step: Stage 2 Crusher

INPUT: Output from Stage 2 (15mm Chunks)

Operational Output: Precision Mincing

To create an excellent cutting result, different hole-plates (from φ4mm to φ35mm) can be selected according to your specific processing requirements.

Works with Column dumper & Chute

High-Volume Bulk Feed

High-Volume Bulk Feed

Consistent Fine Grind

Technical Specifications (Model CM-250)

| Capacity | 3000 - 5000 kg/h (3-5 Tons/hr) |

| Power | 34 kW |

| Screw Speed | 150 rpm |

| Operating Temp | 0°C ~ -10°C |

| Hole Plate Options | φ4, φ6, φ8, φ10, φ13, φ16, φ23, φ28, φ35 mm |

| Machine Dimensions | 2240 x 1070 x 1685 mm |

| Installation Dimensions | 3000 x 1800 x 2500 mm |

| Weight | ≈ 1500 kg |

Dual-Application Technology

The CM-250 is versatile enough for both fresh and frozen applications by utilizing specialized interchangeable screws:

- Fresh Meat Screw: Optimized for cutting fresh meat cleanly without smearing.

- Frozen Meat Screw: Essential for processing frozen blocks or meat/bone mix between -3°C to -10°C. This screw is designed to make the raw meat reach the required product texture efficiently.

- Low Noise & Reliable: The main body and food contact areas are made of quality stainless steel with a reasonable structure for reliable, quiet performance.

OPTIONAL Step 4: Do you need Emulsified Paste?

If your product requires a "soupy" or paste-like consistency (e.g., for hot dogs, lickable pet treats, or liquid fertilizer), the ground output from Stage 3 must be emulsified.

We recommend the Model CM-240 Paste Maker to turn this ground meat into a superfine, micron-level paste.

View Stage 4: Emulsified Paste Maker (CM-240) »

-238x94.jpg)